BOGE Compressed Air Solutions

BOGE KOMPRESSOREN GmbH (Made in Germany) is the World-Class manufacturer of industrial compressors and compressed air systems.

A comprehensive service and maintenance program completes the BOGE advanced & wide portfolio which ensures reliable, clean compressed air for over 110 years. As a proprietor-run family business with its headquarters located in Bielefeld, Germany, BOGE has always focused on the high quality and efficiency of its compressors, resulting in the trust of over 100,000 users in more than 120 countries worldwide.

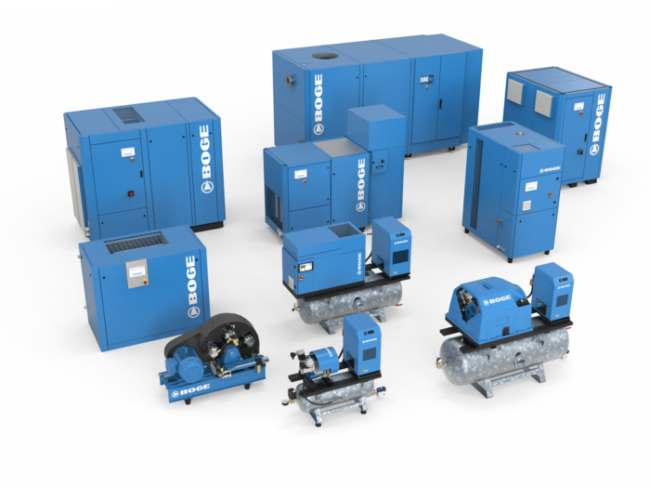

BOGE Compressed Air Products

Air Compressors

“COMPRESSED AIR WITH ADDED VALUE”

Compressed air to meet all requirements and fulfil the most exacting demands – this is what our precision-developed compressors and system solutions are known for. Whether in the food, plastics, steel or pharmaceutical industry: Industrial firms, trade businesses, clinics and hospitals all value the high reliability, efficiency and cost-saving benefits of our products. Our diverse range of compressed air solutions addresses the individual needs of your industry and business. The range spans from individual compressors or compressed air components to complete system and service solutions. In the latter case, we take care not only of the entire installation process, but of the ongoing monitoring and maintenance of your plant. BOGE stands for compressed air that is custom-tailored and adapted to your needs.

Choose from Our Range of BOGE Air Compressors Models

BOGE Air Compressors models you can choose from include:

Screw Compressors

All of BOGE’s screw compressors offer maximum reliability, highly efficient operation and extremely easy maintenance. Whether with oil-injection cooling or oil-free, frequency-controlled, belt-driven or directly coupled – these sturdy machines form the backbone of industry.

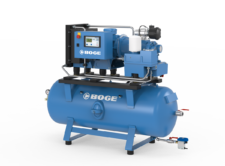

S Eco Series

PRODUCT

Screw compressor with belt-driven drive system, oil-lubricated.

Range: 4 – 30 kW

Pressure range: 7.5 – 10 bar.

ADVANTAGES

- Base control with microprocessor system

- BOGE airend made in Germany.

- Low compressed air temperature due to effective aftercooler

Photo Gallery

S-3 Series

PRODUCT

Screw compressor, oil lubricated.

Range: 22 – 315 kW

Pressure range: 7.5 – 13 bar.

ADVANTAGES

- Heat recovery can be integrated.

- Extremely quiet

- Focus control 2.0.

- Maximum efficiency

- Frequency controlled cooling fan.

Photo Gallery

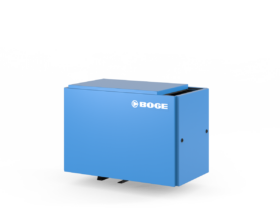

C Series

PRODUCT

Screw compressor, oil lubricated.

Range: 2.2 – 22 kW

Pressure range: 7.5 – 13 bar.

ADVANTAGES

- Compact design

- Extremely quiet

- Maximum efficiency

Photo Gallery

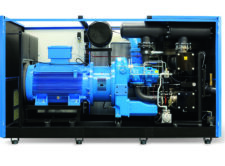

S-4 Series

PRODUCT

Screw compressor, with oil-injection cooling

Range: 55 – 160 kW

Pressure range: 7.5 – 13 bar.

ADVANTAGES

- Effective isolation from vibrations

- Low maintenance airend with optimum efficiency

- Maintenance-friendly design for easy access

- The quietest compressors in their class

Photo Gallery

Screw Compressors Bluekat Series

PRODUCT

Bluekat screw compressor, Oil free air

Range: 30 – 45 kW

Pressure range: 7.5 – 13 bar.

ADVANTAGES

- Heat recovery can be integrated.

- Oil-free compressed air.

- Compact design.

- Extremely quiet.

- Maximum efficiency.

Photo Gallery

SO Series

PRODUCT

Oil-free screw compressor

Range: 45 – 355 kW

Pressure range: 7.5 – 13 bar.

ADVANTAGES

- Heat recovery can be integrated.

- Prime control

- Oil-free compressed air

- Maximum efficiency

Photo Gallery

Piston Compressors

Piston technology that sets standards: BOGE’s P-series brings together its concentrated expertise in the construction of piston compressors. The tried and tested, uniform design principle puts the priority on quality and durability – be it in the skilled trades sector or industry. Thanks to the versatile modular structure, each piston compressor can be upgraded to a customized system – cutting-edge technology that is extremely future-proof!.

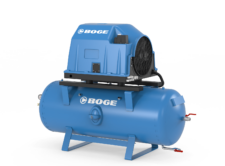

P Series

PRODUCT

Piston compressor oil-lubricated, directly coupled.

Range: 0.6 – 1.3 kW

Pressure range: 10 bar.

ADVANTAGES

- High ambient temperature

- Industrial quality

- Permissible switching frequency unlimited

- Very low maintenance

- Directly coupled.

- Designed for 100% duty cycle.

Photo Gallery

SRD Series

PRODUCT

Oil lubricated piston compressor direct coupled.

Range: 2.2 – 6.3 kW

Pressure range: 10 – 15 bar.

ADVANTAGES

- Directly coupled.

- Designed for 100% duty cycle.

Photo Gallery

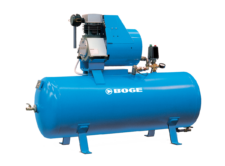

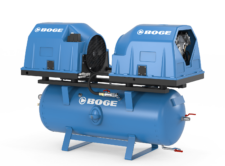

SR, SB, SRM, SRH Series

PRODUCT

Oil lubricated piston compressor.

Range: 1.5 – 15 kW

Pressure range: 10, 15 & 35 bar.

ADVANTAGES

- Designed for 100% duty cycle.

Photo Gallery

SRMV, SRHV Series

PRODUCT

Inlet pressure piston compressor (booster), oil lubricated.

Range: 5.5 – 18.5 kW

Inlet Pressure Range: 5 – 10 bar.

Pressure range: 15 – 40 bar.

ADVANTAGES

- Designed for 100% duty cycle.

- High pressures.

Photo Gallery

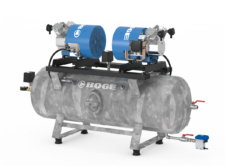

PO Series

PRODUCT

Oil free piston compressor direct coupled.

Range: 2.2 – 5.5 kW

Pressure range: 10 bar.

ADVANTAGES

- Oil-free compressed air

- Directly coupled.

- Designed for 100% duty cycle.

- Maximum efficiency

Photo Gallery

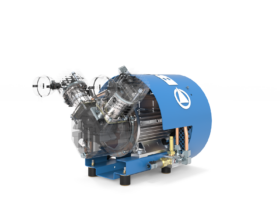

K Series

PRODUCT

Oil free piston compressor direct coupled.

Range: 5.5 – 11 kW

Pressure range: 10, 15 & 40 bar.

ADVANTAGES

- Oil-free compressed air

- Directly coupled.

- Designed for 100% duty cycle.

- Maximum efficiency

Photo Gallery

Scroll Compressors

Ideal for sensitive work environments in which oil-free air and whisper-quiet operation are a must. Smart control allows scroll airends to be switched on or off as required. Efficiency is further improved with a two-stage aftercooler.

EO Series

PRODUCT

Oil-free scroll compressor with a modular design.

Range: 4 – 22 kW

Pressure range: 8 – 10 bar.

ADVANTAGES

- Oil-free compressed air

- Directly coupled.

- Designed for 100% duty cycle.

- Maximum efficiency

Photo Gallery

Compressed Air Treatment

“COMPRESSED AIR – MADE TO MEASURE”

Compressed air is used in a highly diverse range of industries and in a multitude of different ways. Requirements pertaining to its quality and purity vary according to the area of use. Entirely different standards apply for the textile industry than for applications in the food or medical industries, which require 100% oil-free compressed air.

In light of the above, it’s essential that compressed air treatment methods are optimally adapted to their respective area of use. BOGE system components such as compressed air filters and dryers ensure that BOGE compressed air meets the prescribed quality standards of the industry in which it’s used – with optimal efficiency values.

Choose from Our Range of BOGE Air Treatment Models

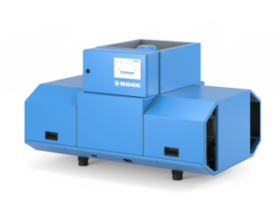

DS-2 Refrigerant Dryer

PRODUCT

Dual-frequency refrigerant dryer

The new DS-2 series features a highly efficient aluminium heat exchanger, which minimises performance losses in the refrigeration cycle and at the same time uses less refrigerant than comparable models. The power consumption is also minimal, making running costs exceptionally low. All models in the new series are fitted as standard with a digital controller, featuring practical functions including status display, floating alarm contact and maintenance reminder. In addition to their superb energy efficiency, the new DS-2 models also have impressively low CO2 emissions ratings. They are designed to run on both 50 and 60 Hz (230 V) power supplies and as such can be used throughout the world. For models with a flow capacity of 2.6 m3/min or more, an additional energy saving option is available, further reducing power consumption in part-load operation.

ADVANTAGES

- Highest quality

- Best energy efficiency

- Digital control

- Minimum operating costs

- Maintenance & service friendly

- Low CO2 footprint

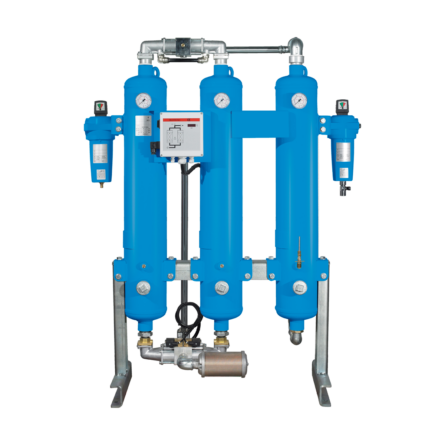

DAZ Series Heatless Regeneration

PRODUCT

Adsorption dryers, heatless regeneration

Extremely dry air with the DAZ series adsorption dryers: Sometimes extremely dry air (i.e. lower than pressure dew point) is required, for example when control or process air applications are used in the food and beverage industries, as well as in the chemical and pharmaceutical industries. This is made possible with an adsorption dryer with a pressure dew point of -40°C (-70°C optional). Take advantage of BOGE’s DAZ Series heatless adsorption dryer, which regenerates a partial stream of dry compressed air parallel to the adsorption of the desiccant.

ADVANTAGES

- Highest quality

- Best energy efficiency

- Digital control

- Ready for connection

- Maintenance & service friendly

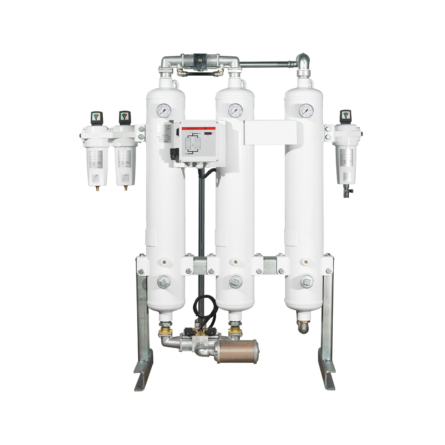

DAV Series External Heated Regeneration and Vacuum Cooling

PRODUCT

Adsorption dryers, external heated regeneration and vacuum cooling

Where large volume flows meet particularly high demands on compressed air quality (pharmaceutical, electrical and automotive industries), BOGE adsorption dryers are the technology of choice: while the moisture is bound to the surface of the high‑quality two‑bed desiccant filling in a receiver (adsorption), the other receiver regenerates. During the regeneration process, ambient air is drawn from the bottom to the top of the receiver over the desiccant bed via a heater and the stored moisture is discharged to the outside. So no purge air needs to be removed from the already dried process air. As a result, the DAV dryers consume up to 25% less energy compared to heatless systems.

ADVANTAGES

- Intelligent control system

- Minimal pressure losses

- Pressure dew points down to -70°C

- Service-friendly

- Thermal insulation

- Zero purge system

DACZ Series Heatless Regeneration and Active Carbon Adsorber

PRODUCT

Adsorption dryers, heatless regeneration and active carbon adsorber

With the BOGE DACZ series, we have combined a cold-regenerated DAZ adsorption dryer with a DCZ activated carbon adsorber. In addition to the pressure dew point of -40°C (-70°C optional) this allows you to limit the residual oil content of the compressed air to 0.003mg/m³.

DASZ Series Adsorption Dryers for Breathing Air

PRODUCT

Adsorption dryers for breathing air

Do you want to efficiently and reliably create compressed air for the most delicate requirements? With the processing units of the DASZ-P Series, you can create breathing air for both industrial and medical purposes. In two chambers, the compressed air is passed through the drier after the pressure swing adsorption has removed any pollutants. Also thanks to the integrated filters plus the detergent and catalyst, the resultant breathing air meets, among other criteria, the standards of the Pharmacopée Européenne.

DH-2 High-Pressure Refrigerant Dryer

PRODUCT

High pressure refrigerant dryers up to 50 bar

Discover the most efficient way to dry compressed air with the BOGE DH-2 series: these refrigerant compressed air dryers boast particularly low energy consumption levels and extremely low pressure losses. This means the two leading cost factors in compressed air drying are reduced to a minimum – meaning maximum efficiency! The DH-2 series also proves it is the premium standard when it comes to sustainability – only high-quality, ozone-friendly refrigerants are used. Used in the performance segment up to 2.25 m³/min, the refrigerant R 513 A stands out due to its very low global warming potential (GWP: 631) and CO2 equivalent.

ADVANTAGES

- Low energy consumption

- Low global warming potential (GWP)

- Low pressure loss

- Reliable pressure dew point

- Smart & ergonomic design

- Low maintenance

F Series FP, FM, FA Compressed Air Filters

PRODUCT

Compressed air filters – Low pressure

With extremely low differential pressure and innovative build, BOGE filters ensure compressed air of the desired purity class.

ADVANTAGES

- 10-year guarantee on housing

- Constantly low differential pressures

- EU-VO 1935/2004 exemption certificate

- Simple, space-saving installation

- Suitable for use with foodstuffs in accordance with FDA Title 21 CFR

- Validated in accordance with ISO 12500 -1:2007 & ISO 8573 -1:2010

F, V, FP, A High-Pressure Compressed Air Filters

PRODUCT

Compressed air filters – High pressure up to 50 bar

BOGE high-pressure filters are available as pre-filter V and also as microfilter FP or activated carbon filter A. All three filters remove solid particles down to 0.01 microns with a separation of 99.99999% from the compressed air. Highly effective microfibre fleeces have a high capacity to absorb dirt while only a low differential pressure is necessary. A pleated depth filter increases the filter area by a factor of 4.5 compared with conventional elements. The design of the filter housing and the filter element are optimised for the flow to have the lowest possible pressure resistance. The high-pressure filters come in 25 and 50 bar versions.

Air Receiver Tanks

PRODUCT

Air receivers.

The compressed air receiver performs several important roles. These include storing the compressed air, separating the condensate as well as its function as a pulsation damper. The materials and workmanship at BOGE are therefore of the highest quality.